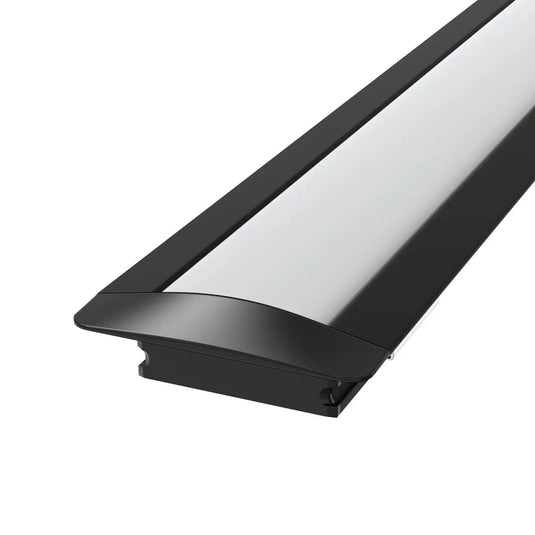

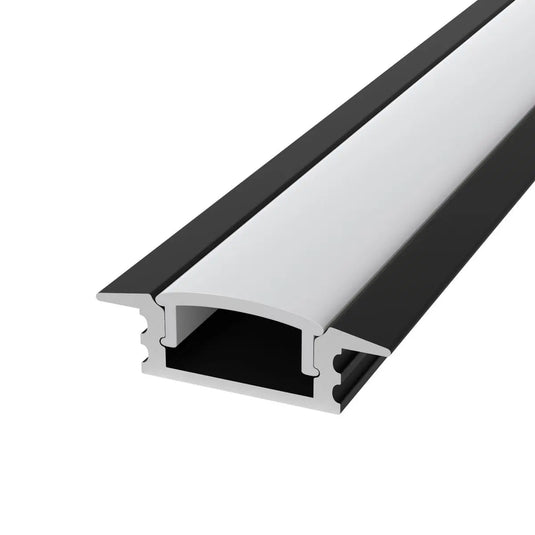

Aluminium LED Profile

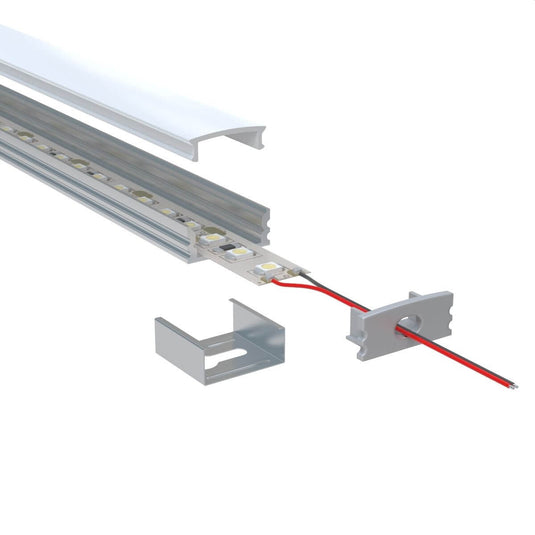

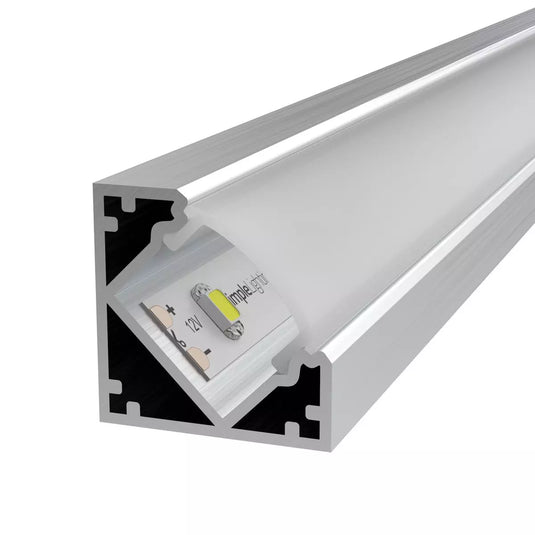

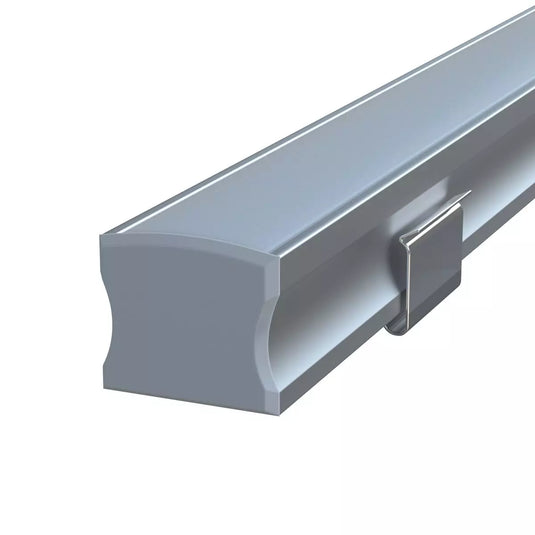

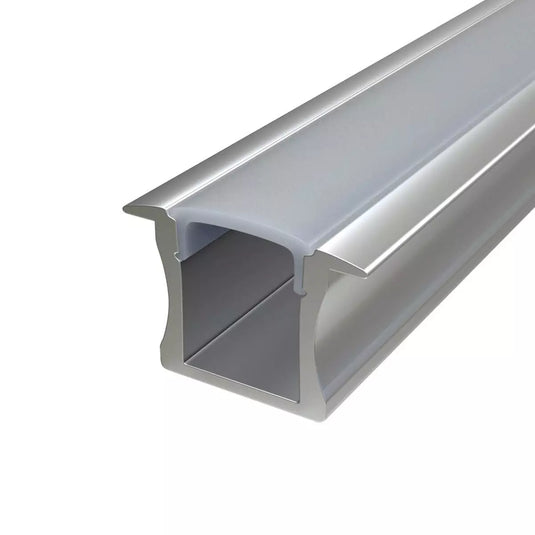

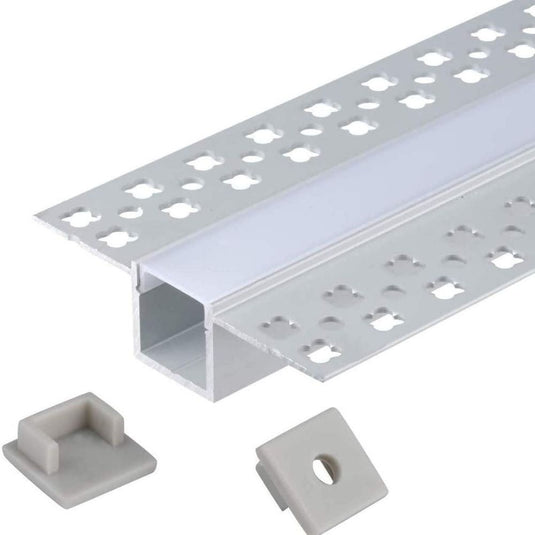

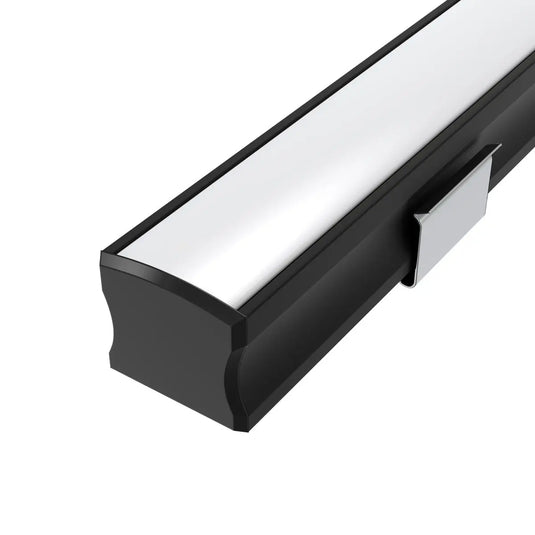

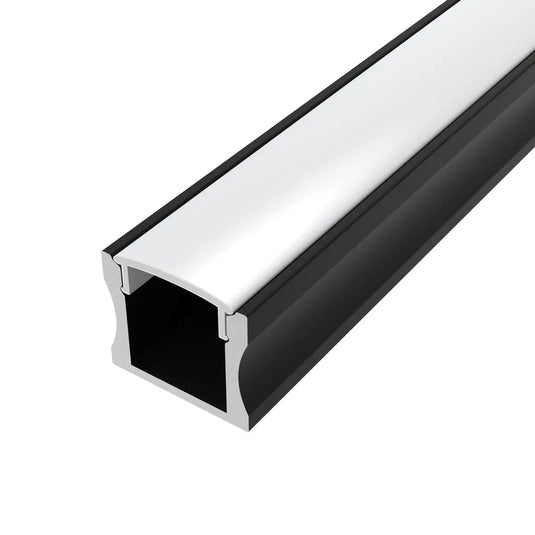

Since LED strip lights are a versatile and widely used lighting solution in residential and commercial premises, it's only fitting that they are kept protected to ensure that they will be kept perfect for their full lifespan. Aluminium LED profiles are designed to keep your strips safe and protected from dust, dirt, faint water splashes, and curious fingers. Giving you more freedom and confidence to place your LED strip lights anywhere that you like.

Aside from their protective feature, aluminium LED profiles can also enhance the visual appeal of your space as they make your LED strip lights look more finished and refined. No more visible circuit boards, only an elegant extrusion elevating your aesthetics.

How to Bend Aluminium Profiles?

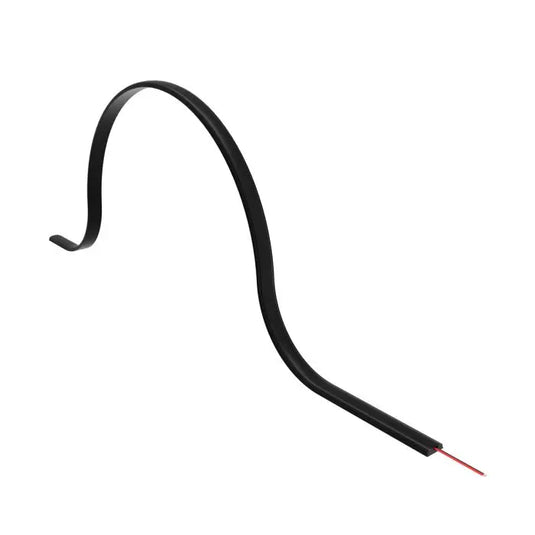

Aluminium profiles come in various types. If you want to bend your profile, it's best to get a bendable kind so you won't have to cut it every time you hit a corner. Bendable aluminium LED profiles are designed to keep up with the flexibility of an LED strip. So, if you're using your LED lights in a rounded ceiling, oval furniture, and curved edges, it's only practical to use a bendable profile for a hassle-free installation.

Straight aluminium LED profiles are impossible or extremely difficult to bend. You’ll have to cut them every time you turn a corner LED profile. So, unless you’re surface mounting your LED strip lights in straight or regular areas, the bendable option is your best bet.

How to Cut Aluminium Profiles?

Cutting aluminium profiles is simple and easy. All you need is the correct tool to make the process a breeze. A quick tip: before you head to your cutting area, mark all your aluminium profiles to the sizes you need, so all that's left is the cutting.

- Set up your saw in a clean and open space - There will be a lot of dust once you start cutting, so make sure that you're in an area that's easy to clean and open.

- Measure the sizes you need - If you haven't done measuring before setting up your saw, this is the time to do it. Be very precise with the measurements because once you cut it, there's no turning back.

- Clamp the profile in place - After marking the measurements, head on to your saw and clamp the profile in place. Make sure that the longest teeth of your blade are in contact with the edge of the profile. Better to double or triple-check before proceeding. (PUT ON SAFETY GOGGLES - nobody wants aluminium particles in their eyes)

- Start Cutting - This part is pretty straightforward. Turn on the saw and bring the blade down to the profile until it's cut. Then, unplug the saw before removing the clamp.

- Clean up - Cutting aluminium can be pretty messy, and aluminium splinters can be sharp so make sure that you clean up really well after you're done.

What is an Aluminium Profile?

Aluminium profiles are also called aluminium LED profiles or LED extrusions. So, if you don't see an aluminium profile in the product list, try looking for its other aliases. What do they do? They act as a guide, channel, or protective housing, so your LED strip profiles are not entirely exposed to various elements. Aluminium profiles will give you more artistic freedom since you don't have to worry about external factors that may affect your lights.

Although aluminium LED profiles provide protection, they are not designed to and cannot guarantee full waterproofing. So, if you plan to add LED strip lights in your bathroom, you still need an IP65-rated light before adding an aluminium profile to make them look better.

... Read More- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old